High Quality Composite Carbon Fiber Autoclave

Product Description

Mechanical And Physical Pressure Composite Carbon Fiber Autoclave

1. The TPC control system (Thermal process control)

1-1 Brief introduction of TPC

The autoclaves components and sensors will be monitored and controlled by the TPC control system. TPC is the Windows XP/Win 7 version of company computerized control software.

1-2 Superior Control is Your Key to Performance

Most will agree that in the world of composites manufacturing, the control system is a key component to assuring autoclave performance, usability, and reliability. Even the best autoclave will be crippled by a poor performing control system, especially when processing large volumes of composites. Because of this fact, OLYMSPAN has focused a large portion of our R&D efforts on our control software and the features/capabilities that can improve processing performance, reliability, and lean manufacturing in autoclaves.

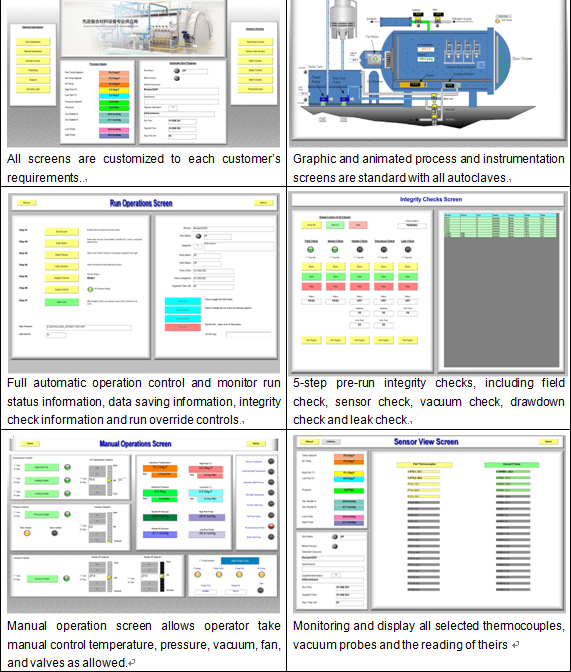

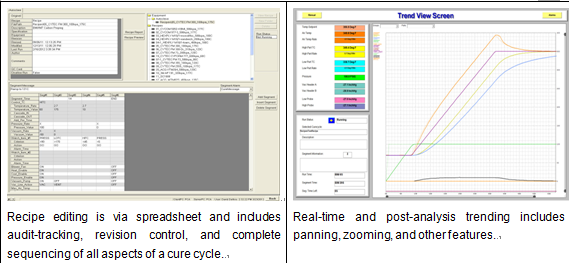

1-3 Sample Screen Images

The following screen images are provided for a typical OLYMSPAN composite autoclave implementation.

2.1 Air Storage tank for Nitrogen7. Assistant equipments for autoclave

2.1.1 Max. working pressure 1.5Mpa

Ø Installation mode: Vertical

Ø Capacity: 12M3

Ø Max pressure: 1.5 Mpa

Ø For the autoclave operating pressure:0.7Mpa

Ø Environment operation temperature: -10℃ - 50℃

Ø Manufacturing standard: GB150-2011, Chinese Pressure Vessel

2.1.2 Max. working pressure 3.0 Mpa

Ø Installation mode: Vertical

Ø Capacity: 8M3

Ø Max pressure: 3.0 Mpa

Ø For the autoclave operating pressure: 1.1 Mpa

Ø Environment operation temperature: -10℃ - 50℃

Ø Manufacturing standard: GB150-2011, Chinese Pressure Vessel

2.2 System of the water preparation

2.2.1 Water pump

Ø Capacity: 8t/h

Ø Head: 30M

Ø Power: 3phase, 380V, 1.5 KW

Ø Material: SUS304

2.2.2 Multi media filter

Ø Capacity: 5t/h

Ø Dimension: Φ1000×1800mm

Ø Material: glass fiber reinforced plastic

Ø Quantity:1pc

Ø Accessory: Pipes and valves

2.2.3 Activated carbon filter

Ø Capacity: 5t/h

Ø Dimension: Φ1000×1800mm

Ø Material: glass fiber reinforced plastic

Ø Quantity:1pc

Ø Accessory: Pipes and valves

2.2.4 Softening filter

Ø Capacity: 5t/h

Ø Dimension: Φ1000×1800mm

Ø Material: glass fiber reinforced plastic

Ø Quantity:1pc

Ø Accessory: Pipes and valves

2.2.5 Sensors, pipes, valves and Instruments

2.3 Circulating water cooling system

This section includes water pump, cooling tower, water tank, filters, valves and pipes.

Ø Type: Open cycle

Ø Quantity: 1 set

Ø Flow rate of pump: 10t/h

Ø Head of pump: 30m

Ø Flow rate of cooling tower: 15t/h

Ø Water tank volume:5cbm

2.4 Platform device , Trolley and installation material

2.4.1 Platform device is used for the loading trolley, it can be moveable.

2.4.2 Trolley is used for part loading and transport, the Length is 4 m. Material is carbon steel with 10 vacuum connections, 10measuring connections (vacuum), 20 connections for thermocouples

2.4.3 Valves , pipes ,flange, gasket and All material for installation of autoclave.

3, Configurations of composite autoclave

Ø PC: Dell

Ø PLC: Siemens

Ø Main electrical component : Schneider

Ø Shell: GB150-2011, CHANGZHOU,CHINA

Ø Heater : Electric heating inconel tubular heaters.

Ø Insulation material: Ceramic fiber

Ø Protect armor: Stainless steel

Ø Heating exchanger:304 stainless-steel, XUELANG, China

Ø SCR: SHIMADEN, China

Ø Electro-pneumatic adjustable Ball Valve: YAMATAKE, Japan

Ø PID controller : Omron ,Japan

Ø Limited Switch: Omron ,Japan

Ø Special Motor: CHANGZHOU, China

Ø Thermocouple: OMEGA

Ø Pressure transducer: KUNLUN, CHINA

Ø Vacuum pump: RUFUS.

Product Categories : Composite Autoclave